Expertise to the minute detail

Small details make all the difference. If you look at the processes and work steps at LP you will notice the following advantages:

We use only genuine components as starting basis. With no exception we use only wear-and-tear parts of the best possible quality available, e.g. bearings from Timken. All wear-and-tear parts are replaced during a restoration without compromise.

All essential spare parts are marked by an LP imprint to document the quality of parts and labour. Each component is rebuild to a standards defined by us, and documented with checklist and pictures. All components completed by LP are dip-cleaned. This enables the most careful and at the same time the most efficient cleaning without the damages typical for the sand plasting process. We accept genuine components as trade in. We deliver worldwide.

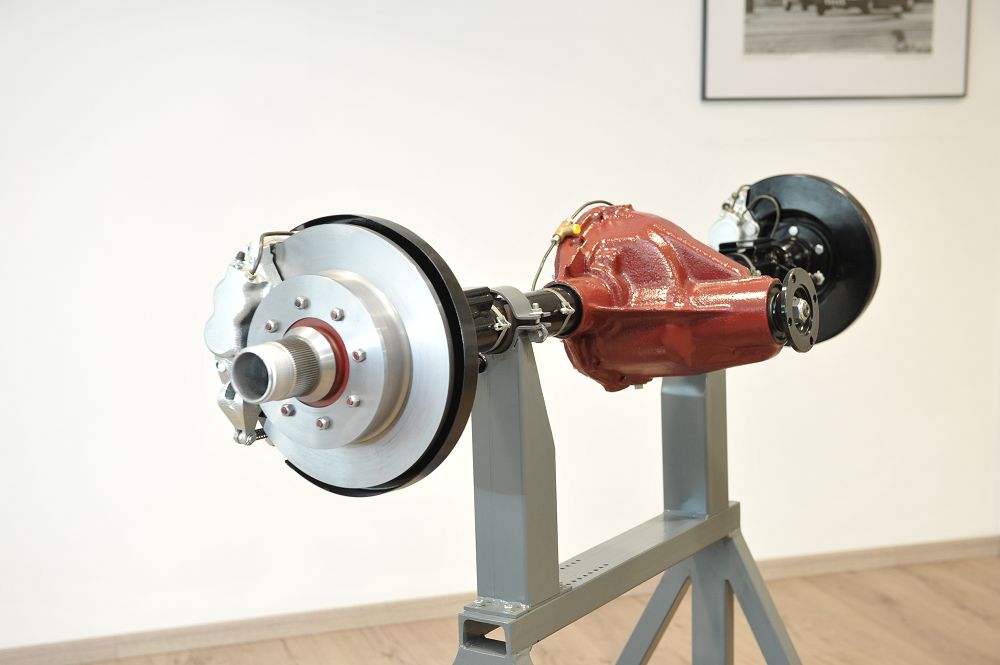

Our offer on components

We repair or overhaul only original and genuine components. All wear-and-tear parts will be replaced by new parts, chosen by us subject to the most stringent quality standards. We offer the following components: